Electric Discharge Machining(EDM)

Precision (Electric Discharge Machining) EDM Services – Complex Cuts with Micron-Level Accuracy.

“Electrically Engineered for Intricate Tooling & Hard Metals”

5/5

EDM

Years of experience

about our Electric Discharge Machining

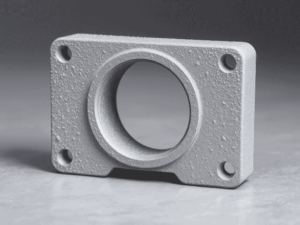

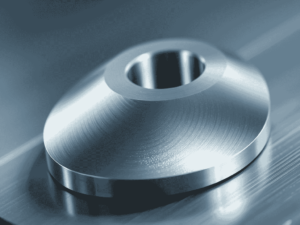

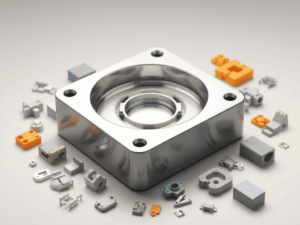

We specialize in precision Electric Discharge Machining (EDM), leveraging advanced spark erosion technology to cut, shape, and machine complex geometries in the toughest materials—from hardened steel to titanium and carbide. Unlike traditional machining, our EDM process delivers micron-level accuracy (±0.0005″) without mechanical stress, making it ideal for intricate tooling, aerospace components, and medical devices. With state-of-the-art sinker (RAM) and wire EDM machines, we ensure burr-free finishes, tight tolerances, and repeatability for high-performance applications. Whether you need prototyping or high-volume production, our expertise guarantees efficiency, reliability, and uncompromising quality.

20,000+ Precision Parts, 150+ Materials

4.9/5

Tolerance Standard

±0.0005" Precision Guarantee

Since 2015

5/5

Surface Finish

C8-16 μin Ra Mirror Finish

Since 2015

4.8/5

Maximum Workpiece

40" × 28" × 20" Capacity

Since 2015

4.5/5

Material Hardness

Up to 65 HRC Processed

Since 2015

Tolerance for Electric Discharge Machining Services

Limits for nominal size

Metals (ISO 2768- f)

Plastics (ISO 2768- m)

0.5mm* to 3mm

±0.05mm

±0.1mm

Over 3mm to 6mm

±0.05mm

±0.1mm

Over 6mm to 30mm

±0.1mm

±0.2mm

Over 30mm to 120mm

±0.15mm

±0.3mm

Over 120mm to 400mm

±0.2mm

±0.5mm

Over 400mm to 1000mm

±0.4mm

±0.8mm

Over 1000mm to 2000mm

±0.5mm

±1.2mm

| Category | Parameter | Standard Grade | Precision Grade | Validation Method |

|---|---|---|---|---|

| Material Properties | Ultimate Tensile Strength | 450 MPa (Al 6061) | 900 MPa (Ti-6Al-4V) | ASTM E8/E21 Testing |

| Thermal Expansion Coeff. | 23.6 μm/m°C (Al) | 8.6 μm/m°C (Invar) | TMA Analysis | |

| Dimensional Control | Positional Tolerance | ±0.005″ | ±0.0008″ | CMM (0.5μm resolution) |

| Surface Profile | 0.010″ | 0.002″ | Laser Scanning | |

| Process Capabilities | Minimum Feature Size | 0.020″ | 0.005″ | Microscope Measurement |

| Aspect Ratio (Depth/Dia.) | 10:1 | 20:1 | Tool Deflection Analysis | |

| Thermal Management | Operating Temp Range | -40°C to +120°C | -196°C to +350°C | Thermal Cycling Tests |

| Thermal Conductivity | 167 W/mK (Cu) | 400 W/mK (CVD Dia.) | Laser Flash Analysis | |

| Surface Engineering | Ra Surface Roughness | 125 μin | 4 μin | White Light Interferometry |

| Coating Thickness | 25-50 μm | 5-10 μm | XRF Measurement | |

| Dynamic Performance | Fatigue Cycles @ 10^6 | 350 MPa | 550 MPa | Resonant Fatigue Testing |

| Vibration Damping | 0.05 ζ | 0.15 ζ | Modal Analysis | |

| Metrology | Measurement Uncertainty | ±0.0002″ | ±0.00005″ | NIST Traceable Standards |

| Flatness/Parallelism | 0.001″/in | 0.0002″/in | Optical Flats | |

| Environmental | Corrosion Resistance | 500h Salt Spray | 2000h Salt Spray | ASTM B117 Testing |

| Outgassing (TML/CVCM) | <1.0%/0.1% | <0.1%/0.01% | NASA ASTM E595 |

Electric Discharge Machining Surface Finishes

We provide finishes for aesthetics and performance: anodizing, polishing, sandblasting, coatings, and heat treatment. Let’s find the right one!

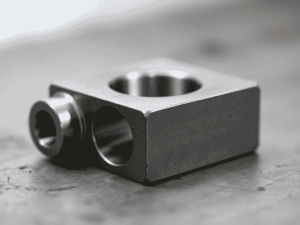

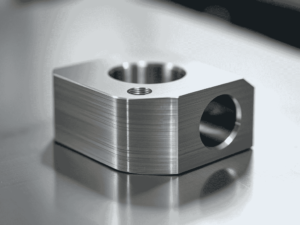

As Machined

This machined finish is rough and displays tool marks, representing the most basic form of surface treatment without any additional finishing or polishing.

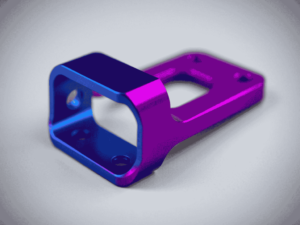

Anodizing

It creates a protective oxide layer on aluminum, increasing corrosion resistance and hardness, and allowing for dyeing to enhance appearance.

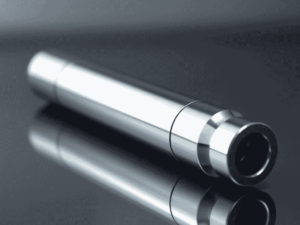

Polishing

Polishing smooths surfaces to a high sheen, enhancing appearance and reducing roughness while offering some corrosion protection.

Brushed Finish

A brushed finish has fine, parallel lines for a textured look, enhancing grip and reducing fingerprints.

Sandblasting

Sandblasting uses high-pressure air and abrasive particles to clean or texture surfaces, enhancing adhesion for coatings.

Electropolish

Electropolishing is an electrochemical process that smooths and brightens metal surfaces, removing imperfections and enhancing corrosion resistance.

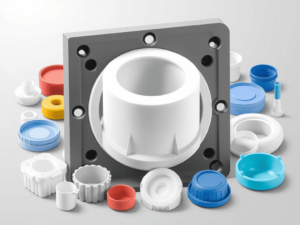

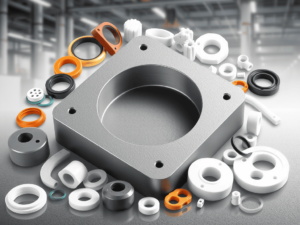

Materials we use for Electric Discharge Machining

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Subtypes:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Subtypes:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Subtypes:

- H11 (Standard)

- H11A (Modified for improved toughness)

Polyoxymethylene (Acetal)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Subtypes:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Subtypes:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Polypropylene

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Subtypes:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Subtypes:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Subtypes:

- LDPE (Standard)

- LDPE (Recycled)

Polycarbonate

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Subtypes:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Subtypes:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Subtypes:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Subtypes:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Subtypes:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Subtypes:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Subtypes:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Subtypes:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Subtypes:

- PTFE (Standard)

- PTFE (Filled)