Custom Laser Cutting – Prototype to Production

“From prototypes to production—laser-cutting metal, wood & acrylic with unmatched precision. Fast service & competitive pricing. “

5/5

EDM

Years of experience

Advanced Laser Cutting & Engraving Services

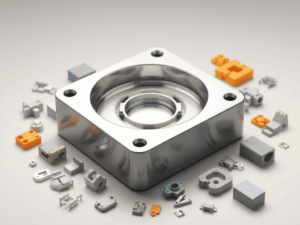

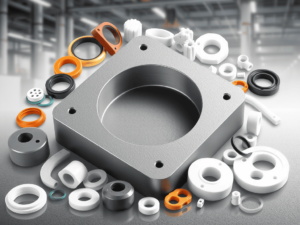

Deliver superior results with our high-precision laser cutting and engraving services, designed for metals, plastics, wood, and composites. Our certified team leverages state-of-the-art CNC laser technology to achieve flawless cuts, detailed engravings, and tight tolerances within ±0.1mm. With over a decade of industry expertise, we adhere to ISO-compliant processes, ensuring consistent quality for engineers, manufacturers, and designers. Whether for prototyping or production, we provide fast turnaround times without compromising precision. Trusted by professionals for repeatable accuracy, we combine technical mastery with reliable performance. Request a quote today for your next project.

20,000+ Precision Parts, 150+ Materials

4.9/5

Tolerance Standard

±0.0005" Precision Guarantee

Since 2015

5/5

Surface Finish

C8-16 μin Ra Mirror Finish

Since 2015

4.8/5

Maximum Workpiece

40" × 28" × 20" Capacity

Since 2015

4.5/5

Material Hardness

Up to 65 HRC Processed

Since 2015

Tolerance for Laser Cutting Services

公称尺寸限值

金属(ISO 2768- f)

塑料(ISO 2768- m)

0.5 毫米* 至 3 毫米

±0.05毫米

±0.1毫米

3 毫米以上至 6 毫米

±0.05毫米

±0.1毫米

6 毫米以上至 30 毫米

±0.1毫米

±0.2毫米

30 毫米以上至 120 毫米

±0.15毫米

±0.3毫米

120 毫米以上至 400 毫米

±0.2毫米

±0.5毫米

400 毫米以上至 1000 毫米

±0.4毫米

±0.8毫米

1000 毫米以上至 2000 毫米

±0.5毫米

±1.2毫米

| Category | Parameter | Standard Grade | Precision Grade | Validation Method |

|---|---|---|---|---|

| Material Properties | Ultimate Tensile Strength | 450 MPa (Al 6061) | 900 MPa (Ti-6Al-4V) | ASTM E8/E21 Testing |

| Thermal Expansion Coeff. | 23.6 μm/m°C (Al) | 8.6 μm/m°C (Invar) | TMA Analysis | |

| Dimensional Control | Positional Tolerance | ±0.005″ | ±0.0008″ | CMM (0.5μm resolution) |

| Surface Profile | 0.010″ | 0.002″ | Laser Scanning | |

| Process Capabilities | Minimum Feature Size | 0.020″ | 0.005″ | Microscope Measurement |

| Aspect Ratio (Depth/Dia.) | 10:1 | 20:1 | Tool Deflection Analysis | |

| Thermal Management | Operating Temp Range | -40°C to +120°C | -196°C to +350°C | Thermal Cycling Tests |

| Thermal Conductivity | 167 W/mK (Cu) | 400 W/mK (CVD Dia.) | Laser Flash Analysis | |

| Surface Engineering | Ra Surface Roughness | 125 μin | 4 μin | White Light Interferometry |

| Coating Thickness | 25-50 μm | 5-10 μm | XRF Measurement | |

| Dynamic Performance | Fatigue Cycles @ 10^6 | 350 MPa | 550 MPa | Resonant Fatigue Testing |

| Vibration Damping | 0.05 ζ | 0.15 ζ | Modal Analysis | |

| Metrology | Measurement Uncertainty | ±0.0002″ | ±0.00005″ | NIST Traceable Standards |

| Flatness/Parallelism | 0.001″/in | 0.0002″/in | Optical Flats | |

| Environmental | Corrosion Resistance | 500h Salt Spray | 2000h Salt Spray | ASTM B117 Testing |

| Outgassing (TML/CVCM) | <1.0%/0.1% | <0.1%/0.01% | NASA ASTM E595 |

Laser Cutting Surface Finishes

我们提供美观和性能兼备的表面处理:阳极氧化、抛光、喷砂、涂层和热处理。让我们找到最合适的产品!

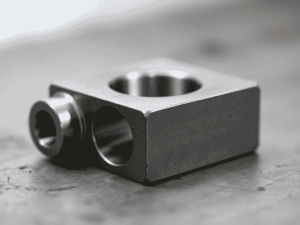

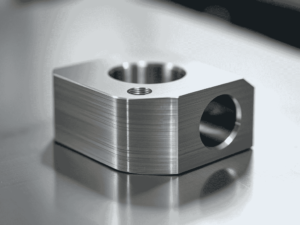

机械加工

这种机加工表面粗糙,有工具痕迹,是最基本的表面处理形式,没有任何额外的精加工或抛光。

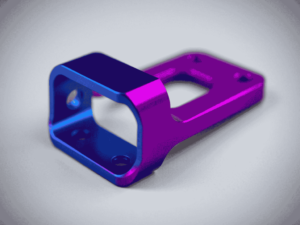

阳极氧化

它能在铝上形成一层保护性氧化层,提高耐腐蚀性和硬度,还能进行染色以改善外观。

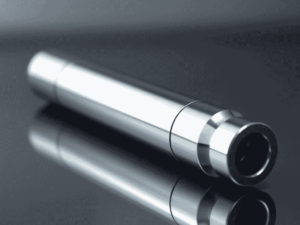

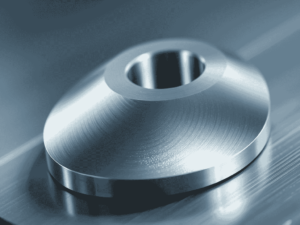

抛光

抛光可使表面光滑如镜,改善外观,减少粗糙度,同时提供一定的防腐蚀保护。

拉丝处理

拉丝表面具有细密的平行线条,看起来质感十足,可增强抓握力并减少指纹。

喷砂

喷砂使用高压空气和研磨颗粒来清洁或纹理表面,从而增强涂层的附着力。

电抛光

电抛光是一种电化学工艺,可使金属表面光滑、光亮,去除瑕疵并增强耐腐蚀性。

Materials we use for solutions

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

亚型:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

亚型:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

亚型:

- H11 (Standard)

- H11A (Modified for improved toughness)

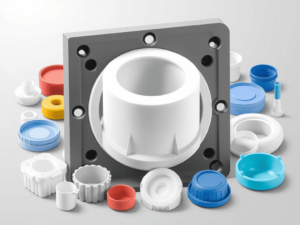

聚甲醛(缩醛)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

亚型:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

亚型:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

聚丙烯

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

亚型:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

亚型:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

亚型:

- LDPE (Standard)

- LDPE (Recycled)

聚碳酸酯

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

亚型:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

亚型:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

亚型:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

亚型:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

亚型:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

亚型:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

亚型:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

亚型:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

亚型:

- PTFE (Standard)

- PTFE (Filled)