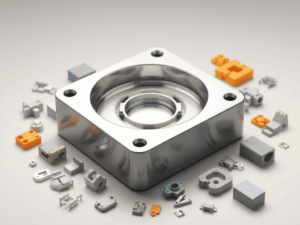

Multi-Axis Machining (3x-axis, 4x-axis, 5x-axis)

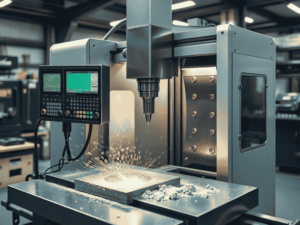

MW+ delivers high-accuracy multi-axis (3-4-5-axis) CNC machining for complex parts. Fast turnaround. Tight tolerances. Trusted by aerospace, medical, and automotive industries.

"Our Multi-Axis Machining Capabilities"

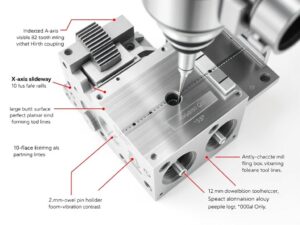

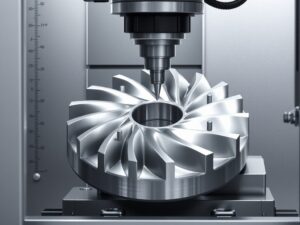

We delivers precision MULTI-AXIS Machining with 3-axis, 4-axis, and 5-axis CNC capabilities for projects of any complexity. Our 3-axis systems provide reliable milling of standard geometries, while 4-axis adds rotary movement for cylindrical parts. For the most intricate components, our 5-axis machines offer full contouring capabilities with simultaneous multi-directional cutting.

We machine aluminum, titanium, plastics, and composites to tolerances of ±0.0005″, handling parts up to [specify dimensions]. Serving aerospace, medical, and automotive industries with ISO-certified precision, we combine advanced technology with decades of machining expertise.

Contact us to optimize your next project with our multi-axis capabilities.

Our Multi-axis Services

3x-axis

3-axis CNC milling for complex 2.5D geometries. Achieve ±0.01mm tolerances in aluminum, steel, and plastics.

4x-axis

4-axis indexed milling for continuous precision on multiple faces. Machine complex contours and angled features (±0.008mm) without repositioning.

5x-axis

5-axis is simultaneous machining for aerospace-grade components. Achieve ±0.005mm tolerances on complex organic shapes

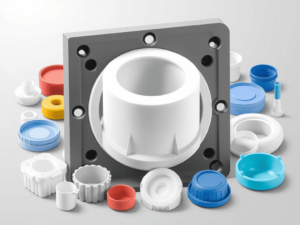

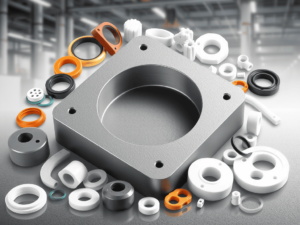

The Materials we provide for our multi-axis services

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Subtipos:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Subtipos:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Subtipos:

- H11 (Standard)

- H11A (Modified for improved toughness)

Polioximetileno (Acetal)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Subtipos:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Subtipos:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Polipropileno

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Subtipos:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Subtipos:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Subtipos:

- LDPE (Standard)

- LDPE (Recycled)

Policarbonato

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Subtipos:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Subtipos:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Subtipos:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Subtipos:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Subtipos:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Subtipos:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Subtipos:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Subtipos:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Subtipos:

- PTFE (Standard)

- PTFE (Filled)

Tolerance for Multi axis Machining Services

Límites para el tamaño nominal

Metales (ISO 2768- f)

Plásticos (ISO 2768- m)

0,5 mm* a 3 mm

±0,05 mm

±0,1 mm

De más de 3 mm a 6 mm

±0,05 mm

±0,1 mm

De más de 6 mm a 30 mm

±0,1 mm

±0,2 mm

De más de 30 mm a 120 mm

±0,15 mm

±0,3 mm

De más de 120 mm a 400 mm

±0,2 mm

±0,5 mm

De más de 400 mm a 1.000 mm

±0,4 mm

±0,8 mm

De más de 1000 mm a 2000 mm

±0,5 mm

±1,2 mm

| Category | Parameter | Standard Grade | Precision Grade | Validation Method |

|---|---|---|---|---|

| Machine Accuracy | Positional Accuracy | ±0.0015″ (3-axis) | ±0.0003″ (5-axis) | Laser Tracker (ISO 230-2) |

| Volumetric Accuracy | ±0.003″ (per ft³) | ±0.0005″ (per ft³) | Ballbar Testing (ISO 230-4) | |

| Tooling Performance | Tool Deflection | <0.002″ @ 10:1 L:D | <0.0005″ @ 20:1 L:D | Strain Gauge Measurement |

| Tool Change Repeatability | ±0.0004″ | ±0.0001″ | Dial Indicator Test | |

| Workholding | Fixture Repeatability | ±0.002″ | ±0.0005″ | CMM Probing (NIST Traceable) |

| Dynamic Clamping Force | 500 lbf (Hydraulic) | 1500 lbf (Pneumatic) | Load Cell Verification | |

| Surface Quality | Ra Surface Finish | 32 μin (End Mill) | 4 μin (Diamond Tool) | White Light Interferometry |

| Form Error (Freeform) | ±0.003″ | ±0.0005″ | 3D Laser Scanning | |

| Process Capabilities | Minimum Feature Size | 0.010″ (3D Contour) | 0.001″ (Micro-Milling) | SEM/ Optical Microscopy |

| Simultaneous Axis Sync | ±15 arc-sec (4th/5th) | ±3 arc-sec (5+ axis) | Rotary Encoder Feedback | |

| Thermal Stability | Thermal Drift (8hr) | ±0.001″/°C | ±0.0002″/°C | Laser Displacement Sensors |

| Coolant Temp Control | ±2°C (Flood Coolant) | ±0.5°C (Chiller System) | Thermocouple Logging | |

| Material Removal | MRR (Aluminum) | 15 in³/min | 50 in³/min (HSM) | Force Dynamometer |

| Hard Material Capability | HRC 45 (Steel) | HRC 65 (Ceramics) | Tool Wear Analysis (SEM) | |

| Dynamic Performance | Vibration Damping | 0.05 ζ (Structural) | 0.20 ζ (Active Control) | Modal Analysis (FFT) |

| Settling Time (Step Response) | 50 ms | 10 ms | High-Speed Encoder Tracking | |

| Metrology Integration | On-Machine Probing | ±0.0005″ (Touch Probe) | ±0.0001″ (Laser Probe) | Master Artifact Calibration |

| Real-Time Error Comp | 50% Error Reduction | 90% Error Reduction | Closed-Loop Feedback System |