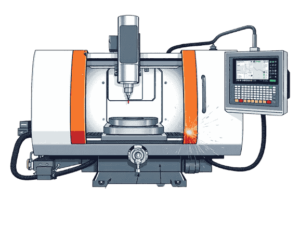

CNC

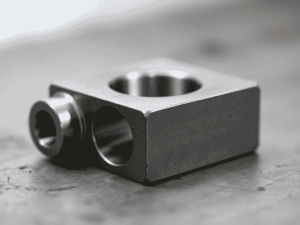

Milling

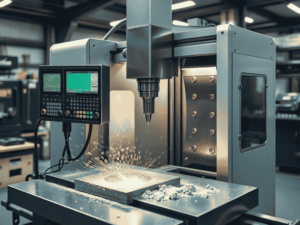

MW+ delivers tight-tolerance precision CNC milling for aerospace, automotive, and medical industries. Our China-based facility utilizes advanced multi-axis machines to craft complex metal and plastic parts with unmatched accuracy. Fast turnaround, scalable from prototypes to full production runs.”

Get precision milling solutions tailored to your needs.”

- 3-axis CNC milling, 4-axis, 5-axis cnc Milling Services are available

- Rapid services, your parts can be shipped as fast as 3 days

- All milling metal and plastic are available

- Tolerances of ±0.005mm are achievable

About our CNC milling

Our high-accuracy CNC milling with multi-axis milling for aerospace, medical, and industrial applications. Our ISO-certified facility produces 10,000+ precision parts annually, achieving tolerances down to ±0.005mm (0.0002″) in metals and plastics.

Key Capabilities:

- 4 & 5-Axis Milling – Complex geometries

- 50+ Material Options – Aluminum, titanium, PEEK

- Fast Lead Times – Prototypes in 5-7 days, production runs in 2-4 weeks

- 99.8% On-Time Delivery – AS9100-compliant quality

MW+'s CNC Milling Services

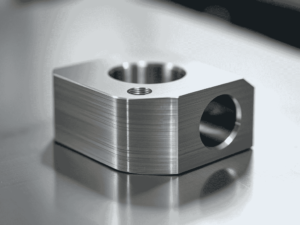

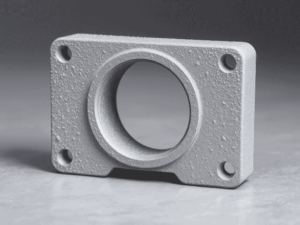

3-axis CNC milling

3-axis CNC milling for complex 2.5D geometries. Achieve ±0.01mm tolerances in aluminum, steel, and plastics.

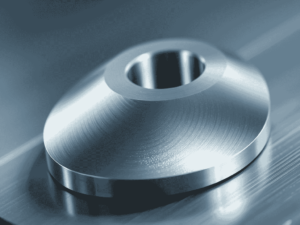

4-axis CNC milling

4-axis indexed milling for continuous precision on multiple faces. Machine complex contours and angled features (±0.008mm) without repositioning.

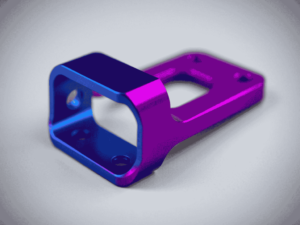

5-axis CNC milling

True 5-axis is simultaneous machining for aerospace-grade components. Achieve ±0.005mm tolerances on complex organic shapes

Precision Micro-Milling

Precision micro-milling is a specialized CNC process that creates ultra-fine, high-tolerance components with micron-level accuracy (±1 µm). Ideal for medical, aerospace, and electronics industries, it uses advanced micro-tools (down to 50 µm) and high-speed spindles for flawless results.

[MW+] delivers top-tier micro-milling solutions for prototypes and production.

Why choosing Us

✅ Sub-Micron Precision – Achieve tolerances within ±1 µm for critical applications.

✅ Advanced Micro-Tools – Diamond-coated & carbide cutters for hard metals & delicate materials.

✅ High-Speed Machining – Fast, burr-free finishes with Ra < 0.2 µm surface quality.

✅ Industry Expertise – Trusted for medical implants, MEMS, and aerospace micro-components.

✅ Full-Scale Production – From prototypes to high-volume orders with quick turnaround.

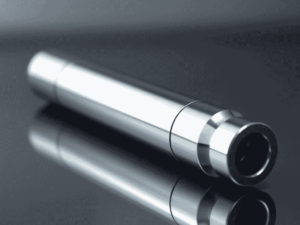

Swiss-Type CNC Milling

Swiss-type CNC milling is an advanced machining technique that excels in producing highly precise and complex components. This method utilizes specialized lathes that allow for exceptional accuracy and efficiency, making it perfect for manufacturing intricate parts in industries such as medical, aerospace, and electronics. Our Swiss-type CNC milling services deliver unmatched quality and precision tailored to your specific requirements.

We are proud to offer top-tier Swiss-type CNC milling services, ensuring your project meets the highest standards.

Why Choose Us?

- Precision Engineering: We guarantee tight tolerances and high accuracy in every component.

- Advanced Technology: Our state-of-the-art machinery enhances efficiency and quality.

- Experienced Team: Our skilled engineers have extensive expertise in CNC milling.

- Custom Solutions: We provide tailored services to meet your unique needs.

- Quick Turnaround: We prioritize timely delivery without compromising quality.

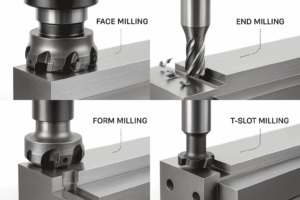

Face Milling

Face milling produces flat surfaces that are perpendicular to the cutter axis. It’s ideal for achieving smooth finishes on workpieces, making it essential in industries like automotive and aerospace.

End Milling

End milling creates slots, grooves, and contours. This versatile process uses specialized tools to shape materials, allowing for intricate designs and functional features in various applications.

Form Milling

Form milling shapes irregular profiles, such as curves and beads. Utilizing specialized tools, it enables the production of unique designs, making it valuable for decorative and custom machinery parts.

T-Slot Milling

T-slot milling cuts T-shaped channels for fixtures and mounting. This process enhances flexibility in machining setups, allowing for secure and adjustable component handling in manufacturing environments.

These featured services represent just one segment of our complete manufacturing solutions portfolio...

"Beyond Standard Manufacturing: We Bring Your Custom Ideas to Life"

"Consult Our Experts"

How does it work?

CNC (Computer Numerical Control) milling is a method used to produce intricate and precise shapes by removing material from a workpiece with a computer-controlled cutting tool. Here’s an overview of the process:

- 设计

The journey begins with creating a 3D digital model of the desired part using computer-aided design (CAD) software. This model is then transformed into a format compatible with the CNC milling machine.

- 编程

The digital design is uploaded to the CNC machine’s control system, where it is converted into machine-readable code (G-code). This code provides detailed instructions on the movement and operation of the cutting tool.

- Setup

Next, the workpiece is securely fastened onto the cnc milling machine’s table using clamps or similar fixtures. The appropriate cutting tool is selected, installed, and calibrated to meet the specifications.

- Milling

With everything in place, the CNC milling machine is activated. Whether performing 3-axis milling for simpler geometries or advanced 5-axis milling for complex contours, the cutting tool precisely follows G-code instructions, systematically removing material. Tool changes or adjustments are made as needed to maintain micron-level precision throughout the process

- 加工

Once milling is complete, the workpiece may undergo additional finishing processes, such as sanding or polishing, to achieve the desired surface quality.

最低订购量(MOQ)

我们提供灵活的最低订购量,以满足小型或原型的要求。

部件总产量

该指标表示生产的零件总数,体现了我们的效率。

设计

多样性

6,000 多种独特设计供您选择,满足各种偏好。

运输 供应情况

我们提供全球送货服务,方便全球用户。

Available materials for Custom CNC Milling

金属

塑料

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

亚型:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

亚型:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

亚型:

- H11 (Standard)

- H11A (Modified for improved toughness)

聚甲醛(缩醛)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

亚型:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

亚型:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

聚丙烯

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

亚型:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

亚型:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

亚型:

- LDPE (Standard)

- LDPE (Recycled)

聚碳酸酯

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

亚型:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

亚型:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

亚型:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

亚型:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

亚型:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

亚型:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

亚型:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

亚型:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

亚型:

- PTFE (Standard)

- PTFE (Filled)

CNC Milling Surface Finishes

我们提供美观和性能兼备的表面处理:阳极氧化、抛光、喷砂、涂层和热处理。让我们找到最合适的产品!

机械加工

这种机加工表面粗糙,有工具痕迹,是最基本的表面处理形式,没有任何额外的精加工或抛光。

阳极氧化

它能在铝上形成一层保护性氧化层,提高耐腐蚀性和硬度,还能进行染色以改善外观。

抛光

抛光可使表面光滑如镜,改善外观,减少粗糙度,同时提供一定的防腐蚀保护。

拉丝处理

拉丝表面具有细密的平行线条,看起来质感十足,可增强抓握力并减少指纹。

喷砂

喷砂使用高压空气和研磨颗粒来清洁或纹理表面,从而增强涂层的附着力。

电抛光

电抛光是一种电化学工艺,可使金属表面光滑、光亮,去除瑕疵并增强耐腐蚀性。

数控铣削服务的公差

公称尺寸限值

金属(ISO 2768- f)

塑料(ISO 2768- m)

0.5 毫米* 至 3 毫米

±0.05毫米

±0.1毫米

3 毫米以上至 6 毫米

±0.05毫米

±0.1毫米

6 毫米以上至 30 毫米

±0.1毫米

±0.2毫米

30 毫米以上至 120 毫米

±0.15毫米

±0.3毫米

120 毫米以上至 400 毫米

±0.2毫米

±0.5毫米

400 毫米以上至 1000 毫米

±0.4毫米

±0.8毫米

1000 毫米以上至 2000 毫米

±0.5毫米

±1.2毫米