CNC Ultrasonic Machining

CNC Ultrasonic Machining – Micron-Level Accuracy in Advanced Materials

“Advanced Vibration Technology for Precision Cutting Without Thermal Stress”

5/5

CNC

Years of experience

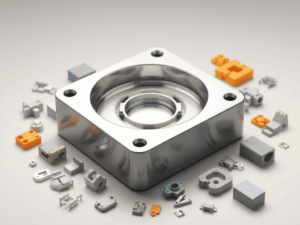

Advanced CNC ultrasonic machining services for complex geometries

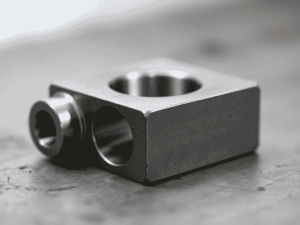

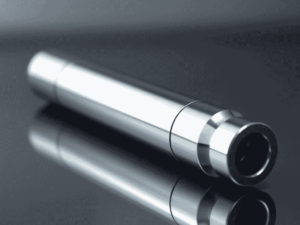

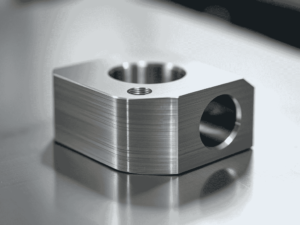

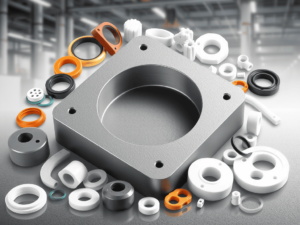

Our advanced CNC ultrasonic machining services delivers micron-level accuracy for the most challenging materials and intricate part. Combining high-frequency ultrasonic vibration with precision CNC control, we achieve what conventional machining cannot – flawless results in ultra-hard, brittle, and temperature-sensitive materials without thermal distortion or micro-fracturing.

Why Our Ultrasonic Machining Stands Apart

Material Expertise: Specialized in machining advanced ceramics (Al₂O₃, ZrO₂, SiC), glass, composites, and superalloys.

Produce micro-holes, intricate cavities, and precision contours with sharp edges and tight tolerances (±0.005mm)

Avoid heat-affected zones (HAZ) critical for medical implants, semiconductor components, and optical devices

Integrates ultrasonic vibration with 5-axis CNC for 3D complex shapes and angled features.

20,000+ Precision Parts, 150+ Materials

4.9/5

Tolerance Standard

±0.0005" Precision Guarantee

Since 2015

5/5

Surface Finish

C8-16 μin Ra Mirror Finish

Since 2015

4.8/5

Maximum Workpiece

40" × 28" × 20" Capacity

Since 2015

4.5/5

Material Hardness

Up to 65 HRC Processed

Since 2015

Tolerance for CNC Ultrasonic Machining Services

Nominal boyut için sınırlar

Metaller (ISO 2768- f)

Plastikler (ISO 2768- m)

0,5 mm* ila 3 mm

±0,05 mm

±0.1mm

3 mm'den 6 mm'ye kadar

±0,05 mm

±0.1mm

6 mm'den 30 mm'ye kadar

±0.1mm

±0,2 mm

30 mm'den 120 mm'ye kadar

±0,15 mm

±0,3 mm

120 mm'den 400 mm'ye kadar

±0,2 mm

±0,5 mm

400 mm'den 1000 mm'ye kadar

±0,4 mm

±0,8 mm

1000 mm'den 2000 mm'ye kadar

±0,5 mm

±1,2 mm

| Category | Parameter | Standard Grade | Precision Grade | Validation Method |

|---|---|---|---|---|

| Material Properties | Ultimate Tensile Strength | 450 MPa (Al 6061) | 900 MPa (Ti-6Al-4V) | ASTM E8/E21 Testing |

| Thermal Expansion Coeff. | 23.6 μm/m°C (Al) | 8.6 μm/m°C (Invar) | TMA Analysis | |

| Dimensional Control | Positional Tolerance | ±0.005″ | ±0.0008″ | CMM (0.5μm resolution) |

| Surface Profile | 0.010″ | 0.002″ | Laser Scanning | |

| Process Capabilities | Minimum Feature Size | 0.020″ | 0.005″ | Microscope Measurement |

| Aspect Ratio (Depth/Dia.) | 10:1 | 20:1 | Tool Deflection Analysis | |

| Thermal Management | Operating Temp Range | -40°C to +120°C | -196°C to +350°C | Thermal Cycling Tests |

| Thermal Conductivity | 167 W/mK (Cu) | 400 W/mK (CVD Dia.) | Laser Flash Analysis | |

| Surface Engineering | Ra Surface Roughness | 125 μin | 4 μin | White Light Interferometry |

| Coating Thickness | 25-50 μm | 5-10 μm | XRF Measurement | |

| Dynamic Performance | Fatigue Cycles @ 10^6 | 350 MPa | 550 MPa | Resonant Fatigue Testing |

| Vibration Damping | 0.05 ζ | 0.15 ζ | Modal Analysis | |

| Metrology | Measurement Uncertainty | ±0.0002″ | ±0.00005″ | NIST Traceable Standards |

| Flatness/Parallelism | 0.001″/in | 0.0002″/in | Optical Flats | |

| Environmental | Corrosion Resistance | 500h Salt Spray | 2000h Salt Spray | ASTM B117 Testing |

| Outgassing (TML/CVCM) | <1.0%/0.1% | <0.1%/0.01% | NASA ASTM E595 |

CNC Ultrasonic Machining Surface Finishes

Estetik ve performans için cilalar sağlıyoruz: eloksal, cilalama, kumlama, kaplamalar ve ısıl işlem. Hadi doğru olanı bulalım!

İşlenmiş Olarak

Bu işlenmiş yüzey pürüzlüdür ve takım izleri gösterir, herhangi bir ek perdahlama veya parlatma olmadan yüzey işlemenin en temel biçimini temsil eder.

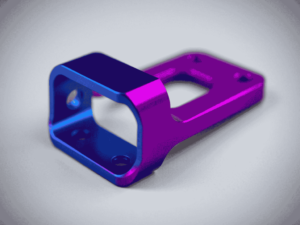

Eloksal

Alüminyum üzerinde koruyucu bir oksit tabakası oluşturarak korozyon direncini ve sertliği artırır ve görünümü iyileştirmek için boyamaya izin verir.

Parlatma

Parlatma, yüzeyleri yüksek parlaklıkta pürüzsüzleştirir, görünümü iyileştirir ve pürüzlülüğü azaltırken bir miktar korozyon koruması sağlar.

Fırçalanmış Kaplama

Fırçalanmış yüzey, dokulu bir görünüm için ince, paralel çizgilere sahiptir, tutuşu artırır ve parmak izlerini azaltır.

Kumlama

Kumlama, yüzeyleri temizlemek veya dokulandırmak için yüksek basınçlı hava ve aşındırıcı parçacıklar kullanır ve kaplamalar için yapışmayı artırır.

Elektropolish

Elektro-parlatma, metal yüzeyleri pürüzsüzleştiren ve parlatan, kusurları gideren ve korozyon direncini artıran elektrokimyasal bir işlemdir.

Materials we use for solutions

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Alt tipler:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Alt tipler:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Alt tipler:

- H11 (Standard)

- H11A (Modified for improved toughness)

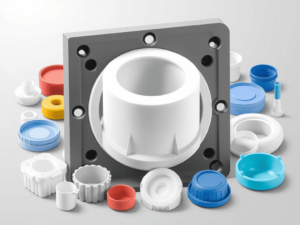

Polioksimetilen (Asetal)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Alt tipler:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Alt tipler:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Polipropilen

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Alt tipler:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Alt tipler:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Alt tipler:

- LDPE (Standard)

- LDPE (Recycled)

Polikarbonat

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Alt tipler:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Alt tipler:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Alt tipler:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Alt tipler:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Alt tipler:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Alt tipler:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Alt tipler:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Alt tipler:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Alt tipler:

- PTFE (Standard)

- PTFE (Filled)