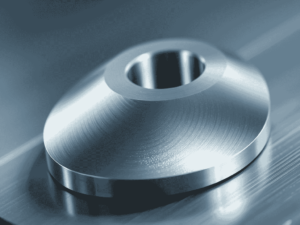

CNC

Milling

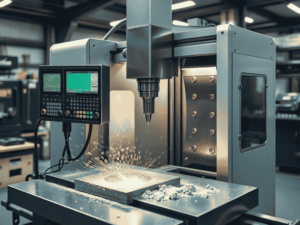

MW+ delivers tight-tolerance precision CNC milling for aerospace, automotive, and medical industries. Our China-based facility utilizes advanced multi-axis machines to craft complex metal and plastic parts with unmatched accuracy. Fast turnaround, scalable from prototypes to full production runs.”

Get precision milling solutions tailored to your needs.”

- 3-axis CNC milling, 4-axis, 5-axis cnc Milling Services are available

- Rapid services, your parts can be shipped as fast as 3 days

- All milling metal and plastic are available

- Tolerances of ±0.005mm are achievable

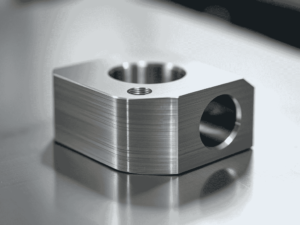

About our CNC milling

Our high-accuracy CNC milling with multi-axis milling for aerospace, medical, and industrial applications. Our ISO-certified facility produces 10,000+ precision parts annually, achieving tolerances down to ±0.005mm (0.0002″) in metals and plastics.

Key Capabilities:

- 4 & 5-Axis Milling – Complex geometries

- 50+ Material Options – Aluminum, titanium, PEEK

- Fast Lead Times – Prototypes in 5-7 days, production runs in 2-4 weeks

- 99.8% On-Time Delivery – AS9100-compliant quality

MW+'s CNC Milling Services

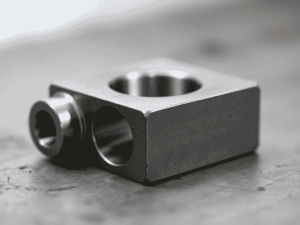

3-axis CNC milling

3-axis CNC milling for complex 2.5D geometries. Achieve ±0.01mm tolerances in aluminum, steel, and plastics.

4-axis CNC milling

4-axis indexed milling for continuous precision on multiple faces. Machine complex contours and angled features (±0.008mm) without repositioning.

5-axis CNC milling

True 5-axis is simultaneous machining for aerospace-grade components. Achieve ±0.005mm tolerances on complex organic shapes

Precision Micro-Milling

Precision micro-milling is a specialized CNC process that creates ultra-fine, high-tolerance components with micron-level accuracy (±1 µm). Ideal for medical, aerospace, and electronics industries, it uses advanced micro-tools (down to 50 µm) and high-speed spindles for flawless results.

[MW+] delivers top-tier micro-milling solutions for prototypes and production.

Why choosing Us

✅ Sub-Micron Precision – Achieve tolerances within ±1 µm for critical applications.

✅ Advanced Micro-Tools – Diamond-coated & carbide cutters for hard metals & delicate materials.

✅ High-Speed Machining – Fast, burr-free finishes with Ra < 0.2 µm surface quality.

✅ Industry Expertise – Trusted for medical implants, MEMS, and aerospace micro-components.

✅ Full-Scale Production – From prototypes to high-volume orders with quick turnaround.

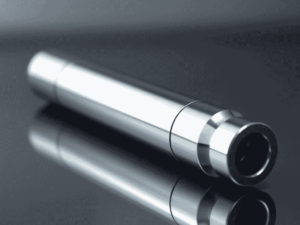

Swiss-Type CNC Milling

Swiss-type CNC milling is an advanced machining technique that excels in producing highly precise and complex components. This method utilizes specialized lathes that allow for exceptional accuracy and efficiency, making it perfect for manufacturing intricate parts in industries such as medical, aerospace, and electronics. Our Swiss-type CNC milling services deliver unmatched quality and precision tailored to your specific requirements.

We are proud to offer top-tier Swiss-type CNC milling services, ensuring your project meets the highest standards.

Why Choose Us?

- Precision Engineering: We guarantee tight tolerances and high accuracy in every component.

- Advanced Technology: Our state-of-the-art machinery enhances efficiency and quality.

- Experienced Team: Our skilled engineers have extensive expertise in CNC milling.

- Custom Solutions: We provide tailored services to meet your unique needs.

- Quick Turnaround: We prioritize timely delivery without compromising quality.

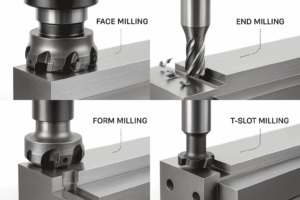

Face Milling

Face milling produces flat surfaces that are perpendicular to the cutter axis. It’s ideal for achieving smooth finishes on workpieces, making it essential in industries like automotive and aerospace.

End Milling

End milling creates slots, grooves, and contours. This versatile process uses specialized tools to shape materials, allowing for intricate designs and functional features in various applications.

Form Milling

Form milling shapes irregular profiles, such as curves and beads. Utilizing specialized tools, it enables the production of unique designs, making it valuable for decorative and custom machinery parts.

T-Slot Milling

T-slot milling cuts T-shaped channels for fixtures and mounting. This process enhances flexibility in machining setups, allowing for secure and adjustable component handling in manufacturing environments.

These featured services represent just one segment of our complete manufacturing solutions portfolio...

"Beyond Standard Manufacturing: We Bring Your Custom Ideas to Life"

"Consult Our Experts"

How does it work?

CNC (Computer Numerical Control) milling is a method used to produce intricate and precise shapes by removing material from a workpiece with a computer-controlled cutting tool. Here’s an overview of the process:

- Tasarım

The journey begins with creating a 3D digital model of the desired part using computer-aided design (CAD) software. This model is then transformed into a format compatible with the CNC milling machine.

- Programlama

The digital design is uploaded to the CNC machine’s control system, where it is converted into machine-readable code (G-code). This code provides detailed instructions on the movement and operation of the cutting tool.

- Setup

Next, the workpiece is securely fastened onto the cnc milling machine’s table using clamps or similar fixtures. The appropriate cutting tool is selected, installed, and calibrated to meet the specifications.

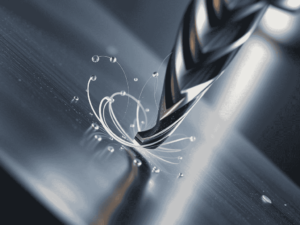

- Milling

With everything in place, the CNC milling machine is activated. Whether performing 3-axis milling for simpler geometries or advanced 5-axis milling for complex contours, the cutting tool precisely follows G-code instructions, systematically removing material. Tool changes or adjustments are made as needed to maintain micron-level precision throughout the process

- Bitirme

Once milling is complete, the workpiece may undergo additional finishing processes, such as sanding or polishing, to achieve the desired surface quality.

Minimum Sipariş Miktarı (MOQ)

Küçük veya prototip talepleri karşılamak için esnek bir minimum sipariş sunuyoruz.

Üretilen Toplam Parça

Bu metrik, üretilen toplam parçaları göstermekte ve verimliliğimizi ortaya koymaktadır.

Tasarım

Çeşitlilik

Her tercihe uygun 6.000'den fazla benzersiz tasarım arasından seçim yapın.

Nakliye Kullanılabilirlik

Küresel erişilebilirlik için dünya çapında nakliye sağlıyoruz.

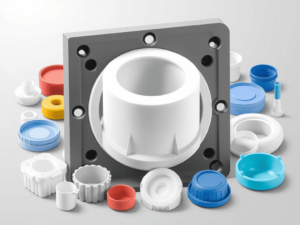

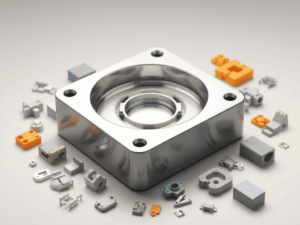

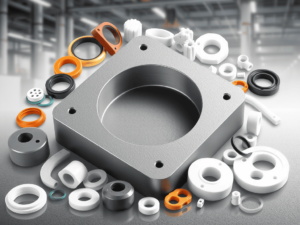

The categories of Products we work with...

All Products made to meet the customer expectation and according to their desire.

General CNC tools

CNC tools are automated machines used for precise cutting and shaping of materials, including end mills, lathes, and drills.

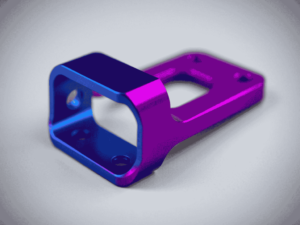

CNC Automotive Parts

CNC automotive parts are precision components made for vehicles, ensuring accuracy and consistency in items like engine blocks and brackets.

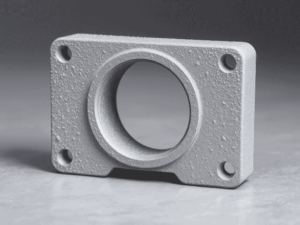

Aerospace components Parts

Precision-engineered parts used in aircraft and spacecraft, critical for safety and performance.

Available materials for Custom CNC Milling

Metaller

Plastikler

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Alt tipler:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Alt tipler:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Alt tipler:

- H11 (Standard)

- H11A (Modified for improved toughness)

Polioksimetilen (Asetal)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Alt tipler:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Alt tipler:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Polipropilen

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Alt tipler:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Alt tipler:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Alt tipler:

- LDPE (Standard)

- LDPE (Recycled)

Polikarbonat

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Alt tipler:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Alt tipler:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Alt tipler:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Alt tipler:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Alt tipler:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Alt tipler:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Alt tipler:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Alt tipler:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Alt tipler:

- PTFE (Standard)

- PTFE (Filled)

CNC Milling Surface Finishes

Estetik ve performans için cilalar sağlıyoruz: eloksal, cilalama, kumlama, kaplamalar ve ısıl işlem. Hadi doğru olanı bulalım!

İşlenmiş Olarak

Bu işlenmiş yüzey pürüzlüdür ve takım izleri gösterir, herhangi bir ek perdahlama veya parlatma olmadan yüzey işlemenin en temel biçimini temsil eder.

Eloksal

Alüminyum üzerinde koruyucu bir oksit tabakası oluşturarak korozyon direncini ve sertliği artırır ve görünümü iyileştirmek için boyamaya izin verir.

Parlatma

Parlatma, yüzeyleri yüksek parlaklıkta pürüzsüzleştirir, görünümü iyileştirir ve pürüzlülüğü azaltırken bir miktar korozyon koruması sağlar.

Fırçalanmış Kaplama

Fırçalanmış yüzey, dokulu bir görünüm için ince, paralel çizgilere sahiptir, tutuşu artırır ve parmak izlerini azaltır.

Kumlama

Kumlama, yüzeyleri temizlemek veya dokulandırmak için yüksek basınçlı hava ve aşındırıcı parçacıklar kullanır ve kaplamalar için yapışmayı artırır.

Elektropolish

Elektro-parlatma, metal yüzeyleri pürüzsüzleştiren ve parlatan, kusurları gideren ve korozyon direncini artıran elektrokimyasal bir işlemdir.

CNC Freze Hizmetleri için Tolerans

Nominal boyut için sınırlar

Metaller (ISO 2768- f)

Plastikler (ISO 2768- m)

0,5 mm* ila 3 mm

±0,05 mm

±0.1mm

3 mm'den 6 mm'ye kadar

±0,05 mm

±0.1mm

6 mm'den 30 mm'ye kadar

±0.1mm

±0,2 mm

30 mm'den 120 mm'ye kadar

±0,15 mm

±0,3 mm

120 mm'den 400 mm'ye kadar

±0,2 mm

±0,5 mm

400 mm'den 1000 mm'ye kadar

±0,4 mm

±0,8 mm

1000 mm'den 2000 mm'ye kadar

±0,5 mm

±1,2 mm

Talk to us

Çevrimiçi alıntılar

SON HABERLER

Machining cost

CNC işleme (Computer Numerical Control machining) is a precise tools to shape and .. learn more..