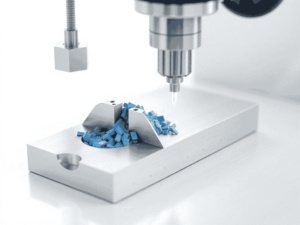

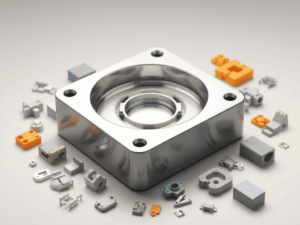

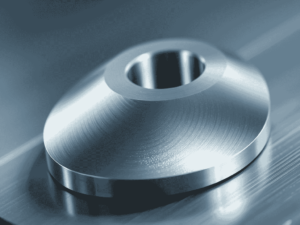

Machine Parts Manufacturing

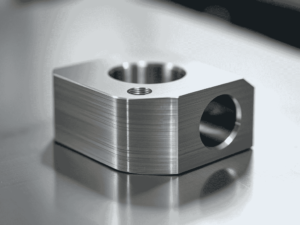

As a leading provider of mission-critical machines parts, MW+ delivers manufacturing excellence through advanced CNC machined technologies and rigorous quality systems. Our AS9100 and ISO 13485 certified facilities specialize in high-precision production of complex components for the most demanding applications across aerospace, medical, and industrial sectors.

- Custom parts manufacturing capability

- Tolerances down to ±0.0004″ (0.01mm)

- Available rapid prototyping and mass production

About Our parts manufacturing

Our mission-critical machine parts engineered to exacting specifications for the world’s most demanding industries. Our AS9100 & ISO 13485 certified manufacturing ecosystem integrates advanced Micro machining, Swiss precision turning, and wire EDM technologies to produce components with:

Uncompromising Specifications:

Tolerances to ±0.0004″ (GD&T compliant)

Material Expertise: Titanium, Inconel, PEEK, and advanced composites

Full Production Scalability: Prototype to high-volume (250,000+ units annually)

Regulatory Compliance: ITAR, NADCAP, and industry-specific certifications. wiki info

MW+'s types of machine parts manufacturing

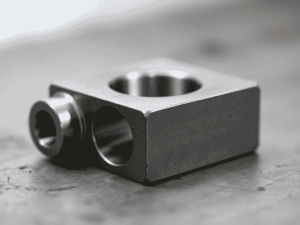

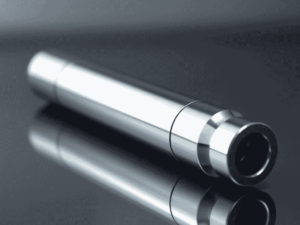

Swiss Machining

Ultra-precision Swiss-turned parts for medical, aerospace, and electronics applications. Our CNC Swiss machining produce complex, miniature parts (0.5–32mm diameter) with micron-level accuracy in titanium, stainless steel, and engineered plastics.

Micro-Machining

We delivers ultra-fine micro parts for medical devices, micro-optics, and microelectronics. Our advanced processes achieve features as small as 20µm in metals, ceramics, and engineered polymers with uncompromising accuracy.

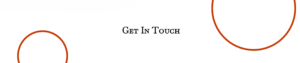

High-Speed Machining (HSM)

Achieve faster production cycles without sacrificing precision with our advanced high-speed machining capabilities. We specialize in optimized material removal for complex parts requiring tight tolerances (±0.01mm) and superior surface finishes (Ra <0.4µm).

Composite Machine parts

MetalWorks+ specializes in precision machining of engineered composites machine parts for mission-critical industries. Our proprietary processes overcome the unique challenges of composite materials while delivering aerospace-grade accuracy.

Key Differentiators:

• Delamination-Free Machining – Proprietary tooling and techniques prevent fiber separation

• Material-Specific Solutions – Optimized for CFRP, GFRP, Kevlar®, and ceramic matrix composites

• Ultra-Precise Tolerances – Achieve high precision on complex geometries

• Surface Integrity – Specialized edge finishing prevents micro-cracking

• Industry Compliance – Meet Boeing BAC 5313, Airbus AITM, and NADCAP standards. wiki info

Cryogenic Machine parts

Our cryogenic machining process utilizes liquid nitrogen cooling to enable precision machining of high-performance alloys and composites. This advanced technique delivers measurable improvements in:

Technical Benefits:

• 300% increase in tool life versus conventional machining

• Maintenance of ±0.01mm tolerances in extreme conditions

• Elimination of heat-affected zones in workpieces

Material Specialization:

Nickel-based superalloys (Inconel 718, Waspaloy)

Titanium alloys (Ti-6Al-4V)

High-strength composites

Минимальное количество заказа (MOQ)

Мы предлагаем гибкий минимальный заказ, чтобы удовлетворить небольшие запросы или запросы на изготовление прототипов.

Общее количество произведенных деталей

Эта метрика показывает общее количество произведенных деталей, демонстрируя нашу эффективность.

Дизайн

Разнообразие

Выбирайте из более чем 6 000 уникальных дизайнов на любой вкус.

Доставка Наличие

Мы обеспечиваем доставку по всему миру для глобальной доступности.

These featured services represent just one segment of our complete manufacturing solutions portfolio...

"Beyond Standard Manufacturing: We Bring Your Custom Ideas to Life"

"Consult with Our Experts"

Металлы

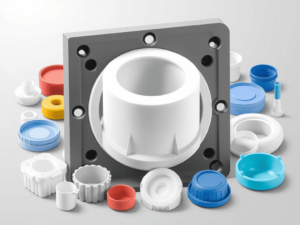

Пластмассы

Available materials for machine parts Services

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Подтипы:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Подтипы:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Подтипы:

- H11 (Standard)

- H11A (Modified for improved toughness)

Полиоксиметилен (ацеталь)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Подтипы:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Подтипы:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Полипропилен

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Подтипы:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Подтипы:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Подтипы:

- LDPE (Standard)

- LDPE (Recycled)

Поликарбонат

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Подтипы:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Подтипы:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Подтипы:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Подтипы:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Подтипы:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Подтипы:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Подтипы:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Подтипы:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Подтипы:

- PTFE (Standard)

- PTFE (Filled)

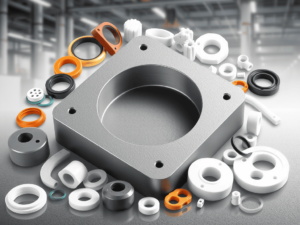

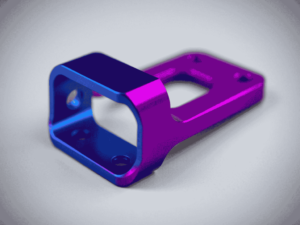

Machine Parts Surface Finishes

Мы обеспечиваем эстетическую и эксплуатационную отделку: анодирование, полировку, пескоструйную обработку, нанесение покрытий и термообработку. Давайте найдем подходящий вариант!

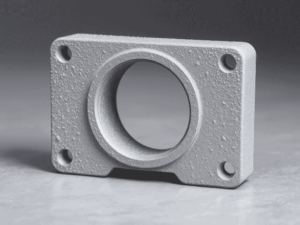

Как обработано

Такая обработка является грубой и имеет следы от инструмента, представляя собой самую базовую форму обработки поверхности без дополнительной отделки или полировки.

Анодирование

Он создает защитный оксидный слой на алюминии, повышая коррозионную стойкость и твердость, а также позволяя окрашивать его для улучшения внешнего вида.

Полировка

Полировка сглаживает поверхности до блеска, улучшая внешний вид и уменьшая шероховатость, а также обеспечивая некоторую защиту от коррозии.

Матовая отделка

Матовое покрытие с тонкими параллельными линиями придает текстуру, улучшает захват и уменьшает отпечатки пальцев.

Пескоструйная обработка

Пескоструйная обработка использует воздух под высоким давлением и абразивные частицы для очистки или текстурирования поверхностей, повышая адгезию покрытий.

Электрополировка

Электрополировка - это электрохимический процесс, который сглаживает и осветляет металлические поверхности, устраняя дефекты и повышая коррозионную стойкость.

Предельные значения номинального размера

Металлы (ISO 2768- f)

Пластмассы (ISO 2768- m)

0,5 мм* - 3 мм

±0,05 мм

±0,1 мм

От 3 мм до 6 мм

±0,05 мм

±0,1 мм

От 6 мм до 30 мм

±0,1 мм

±0,2 мм

От 30 мм до 120 мм

±0,15 мм

±0,3 мм

От 120 мм до 400 мм

±0,2 мм

±0,5 мм

От 400 мм до 1000 мм

±0,4 мм

±0,8 мм

От 1000 мм до 2000 мм

±0,5 мм

±1,2 мм

Tolerance for Machine parts Services