CNC

Milling

MW+ delivers tight-tolerance precision CNC milling for aerospace, automotive, and medical industries. Our China-based facility utilizes advanced multi-axis machines to craft complex metal and plastic parts with unmatched accuracy. Fast turnaround, scalable from prototypes to full production runs.”

Get precision milling solutions tailored to your needs.”

- 3-axis CNC milling, 4-axis, 5-axis cnc Milling Services are available

- Rapid services, your parts can be shipped as fast as 3 days

- All milling metal and plastic are available

- Tolerances of ±0.005mm are achievable

About our CNC milling

Our high-accuracy CNC milling with multi-axis milling for aerospace, medical, and industrial applications. Our ISO-certified facility produces 10,000+ precision parts annually, achieving tolerances down to ±0.005mm (0.0002″) in metals and plastics.

Key Capabilities:

- 4 & 5-Axis Milling – Complex geometries

- 50+ Material Options – Aluminum, titanium, PEEK

- Fast Lead Times – Prototypes in 5-7 days, production runs in 2-4 weeks

- 99.8% On-Time Delivery – AS9100-compliant quality

MW+'s CNC Milling Services

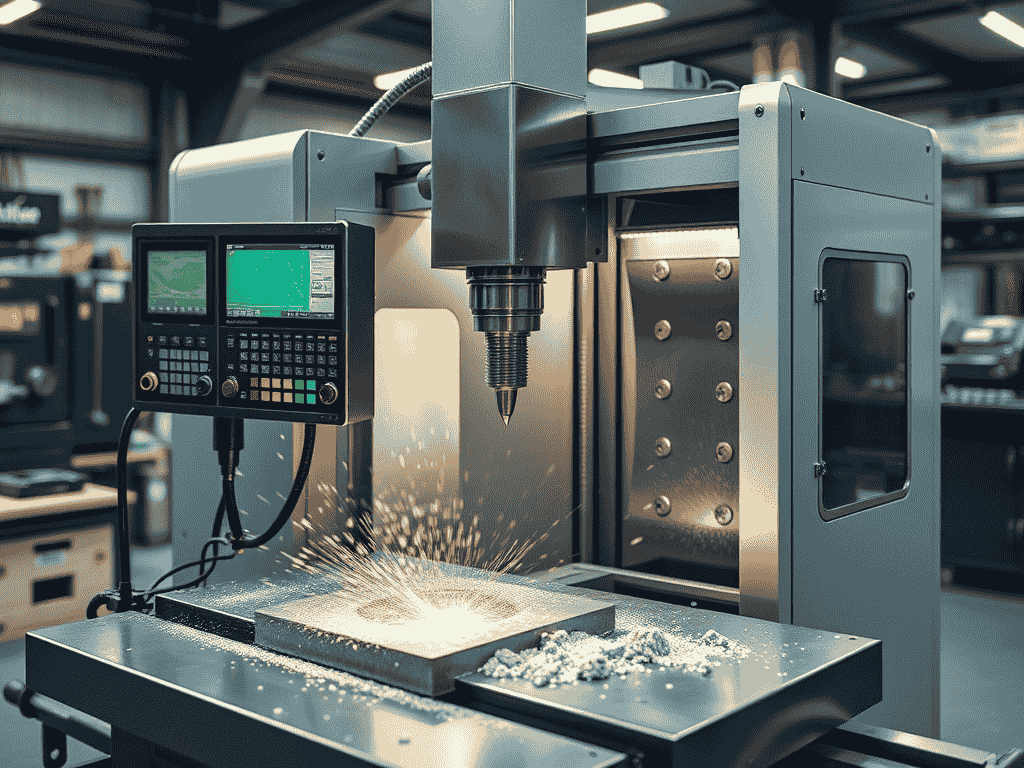

3-axis CNC milling

3-axis CNC milling for complex 2.5D geometries. Achieve ±0.01mm tolerances in aluminum, steel, and plastics.

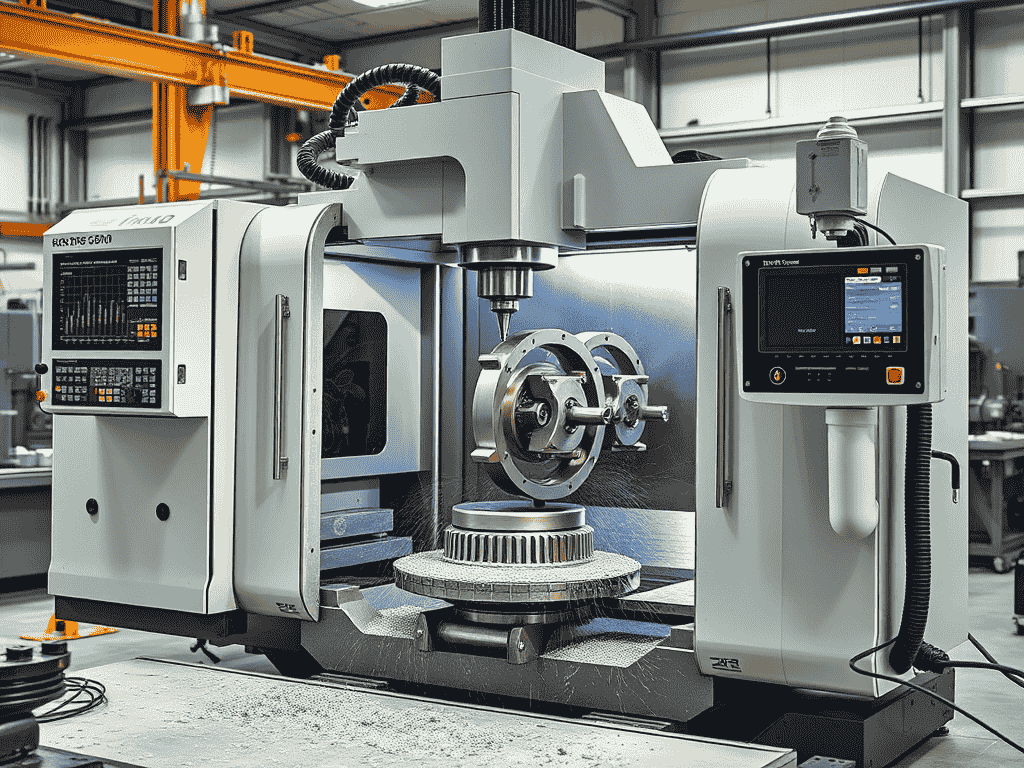

4-axis CNC milling

4-axis indexed milling for continuous precision on multiple faces. Machine complex contours and angled features (±0.008mm) without repositioning.

5-axis CNC milling

True 5-axis is simultaneous machining for aerospace-grade components. Achieve ±0.005mm tolerances on complex organic shapes

These featured services represent just one segment of our complete manufacturing solutions portfolio...

"Beyond Standard Manufacturing: We Bring Your Custom Ideas to Life"

"Consult Our Experts"

How does it work?

CNC (Computer Numerical Control) milling is a method used to produce intricate and precise shapes by removing material from a workpiece with a computer-controlled cutting tool. Here’s an overview of the process:

- Design

The journey begins with creating a 3D digital model of the desired part using computer-aided design (CAD) software. This model is then transformed into a format compatible with the CNC milling machine.

- Programming

The digital design is uploaded to the CNC machine’s control system, where it is converted into machine-readable code (G-code). This code provides detailed instructions on the movement and operation of the cutting tool.

- Setup

Next, the workpiece is securely fastened onto the cnc milling machine’s table using clamps or similar fixtures. The appropriate cutting tool is selected, installed, and calibrated to meet the specifications.

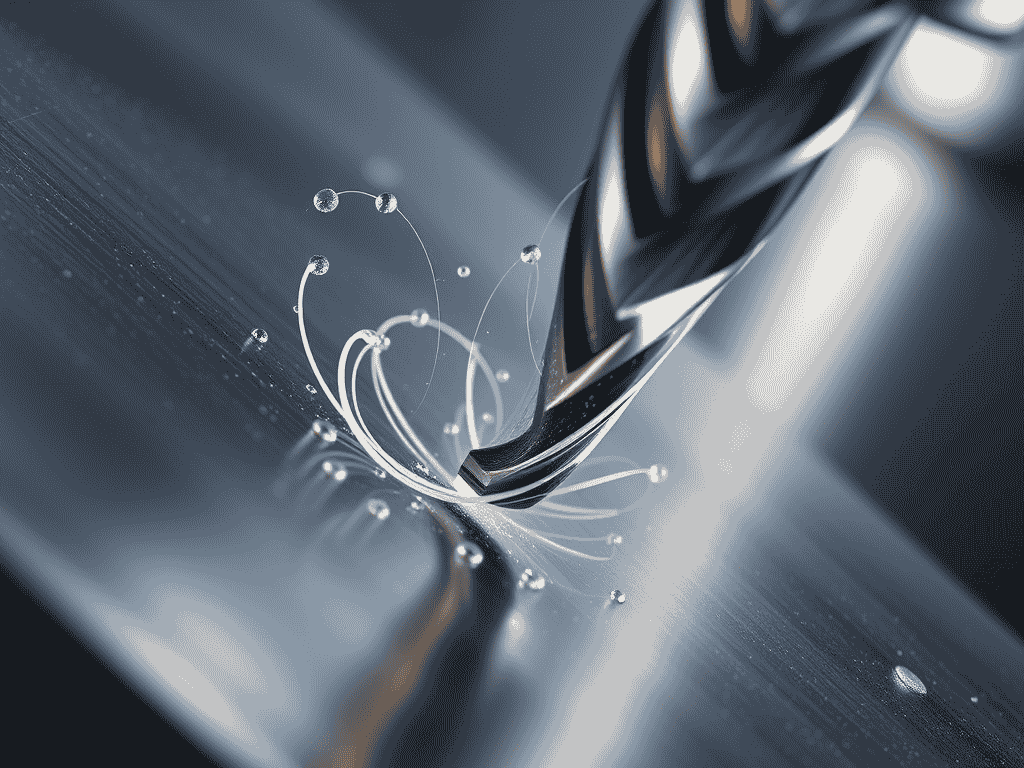

- Milling

With everything in place, the CNC milling machine is activated. Whether performing 3-axis milling for simpler geometries or advanced 5-axis milling for complex contours, the cutting tool precisely follows G-code instructions, systematically removing material. Tool changes or adjustments are made as needed to maintain micron-level precision throughout the process

- Finishing

Once milling is complete, the workpiece may undergo additional finishing processes, such as sanding or polishing, to achieve the desired surface quality.

Minimum Order Quantity (MOQ)

We offer a flexible minimum order to accommodate small or prototype requests.

Total Parts Produced

This metric indicates total parts produced, demonstrating our efficiency.

Design

Variety

Choose from over 6,000 unique designs for every preference.

Shipping Availability

We provide worldwide shipping for global accessibility.

The categories of Products we work with...

All Products made to meet the customer expectation and according to their desire.

General CNC tools

CNC tools are automated machines used for precise cutting and shaping of materials, including end mills, lathes, and drills.

CNC Automotive Parts

CNC automotive parts are precision components made for vehicles, ensuring accuracy and consistency in items like engine blocks and brackets.

Aerospace components Parts

Precision-engineered parts used in aircraft and spacecraft, critical for safety and performance.

Available materials for Custom CNC Milling

Metals

Plastics

Aluminum

Aluminum is a lightweight, corrosion-resistant metal favored for its excellent machinability and strength-to-weight ratio. It’s widely used in aerospace, automotive, and consumer goods industries.

- 6061 Aluminum

- 7075 Aluminum

Steel

Steel is a durable metal available in various grades, making it versatile for CNC milling. It’s commonly used in machinery, tools, and automotive parts.

- Stainless Steel

- Tool Steel

Brass

Brass is an alloy of copper and zinc, known for excellent machinability and corrosion resistance. It’s commonly used in electrical fittings and decorative applications.

- Free-Cutting Brass

- Architectural Brass

Titanium

Titanium is a lightweight, high-strength metal with exceptional corrosion resistance, ideal for aerospace and medical applications.

- Grade 5 Titanium (Ti-6Al-4V)

- Grade 2 Titanium

Copper

Copper is highly conductive and malleable, making it ideal for electrical applications and heat exchangers.

- Electrolytic Copper

- Copper Alloys

Nickel Alloys

Nickel alloys are known for heat and corrosion resistance, suitable for high-performance applications in aerospace and chemical industries.

- Inconel

- Monel

Acrylonitrile Butadiene Styrene

ABS is a versatile thermoplastic known for its impact resistance and toughness. Commonly used in consumer goods, automotive parts, and electronic housings.

Subtypes:

- Standard ABS

- Flame-Retardant ABS

- High-Impact ABS

Polypropylene

Polypropylene is a lightweight, chemical-resistant thermoplastic that exhibits excellent fatigue resistance. It is widely used in packaging, automotive components, and household goods.

Subtypes:

- Homopolymer PP

- Copolymer PP

- Random Copolymer PP

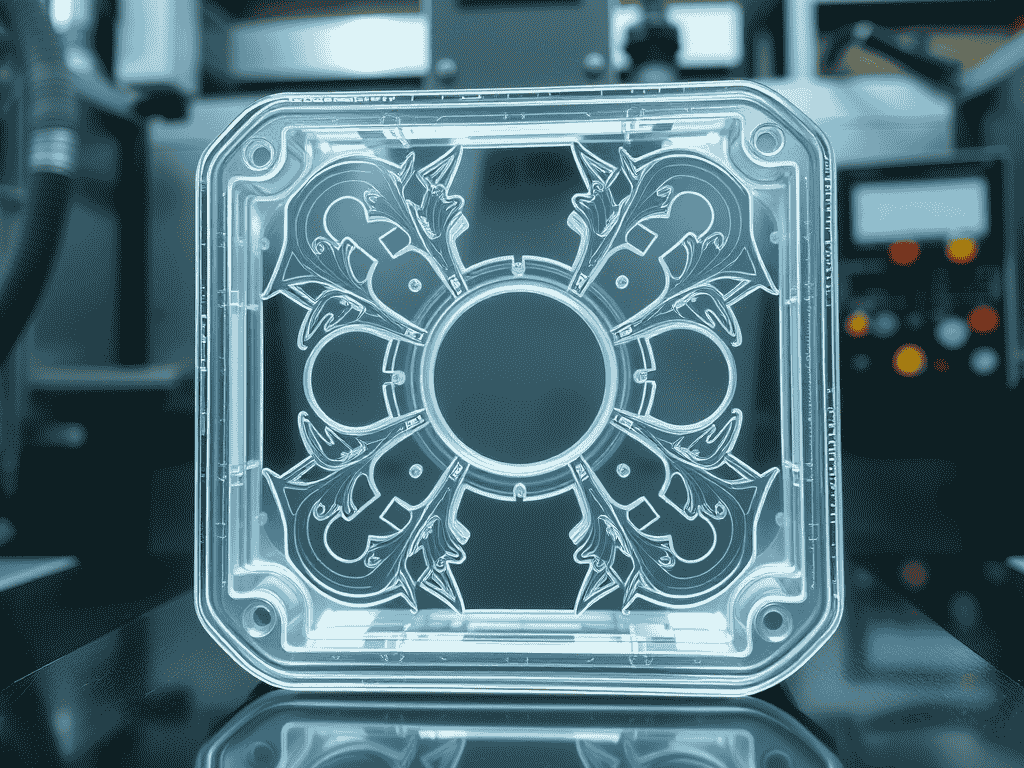

Polycarbonate

Polycarbonate is a high-performance plastic known for its exceptional impact resistance and optical clarity. It is often used in applications like eyewear lenses, safety shields, and automotive parts.

Subtypes:

- Standard PC

- High-Heat PC

- UV-Stabilized PC

Polyoxymethylene (Acetal)

POM, also known as Acetal, is a strong thermoplastic with excellent dimensional stability and low friction properties. It is commonly used in precision parts, gears, and bearings.

Subtypes:

- Homopolymer POM

- Copolymer POM

Polyvinyl Chloride

PVC is a versatile thermoplastic that is resistant to weathering and chemicals. It is widely used in construction, pipes, and electrical cable insulation.

Subtypes:

- Rigid PVC

- Flexible PVC

- CPVC (Chlorinated PVC)

Polyethylene Terephthalate

PET is a strong, heat-resistant thermoplastic commonly used for packaging and textiles. It offers excellent clarity and is often used for bottles and containers.

Subtypes:

- Standard PET

- PETG (Glycol-Modified PET)

Nylon 6/6

Nylon 6/6 is a specific type of nylon with excellent strength and heat resistance. It is commonly used in applications requiring durability, such as automotive parts and industrial components.

Subtypes:

- Glass-Filled Nylon 6/6

- Flame-Retardant Nylon 6/6

Glycol-Modified Polyethylene Terephthalate

PETG is a clear thermoplastic known for its impact resistance and ease of processing. It is commonly used in packaging, medical devices, and signage.

Subtypes:

- Standard PETG

- High-Clarity PETG

Our Custom CNC milling Company

On the surface these are our overall process for manufacturing your dreams.

CNC Milling Surface Finishes

We provide finishes for aesthetics and performance: anodizing, polishing, sandblasting, coatings, and heat treatment. Let’s find the right one!

As Machined

This machined finish is rough and displays tool marks, representing the most basic form of surface treatment without any additional finishing or polishing.

Anodizing

It creates a protective oxide layer on aluminum, increasing corrosion resistance and hardness, and allowing for dyeing to enhance appearance.

Polishing

Polishing smooths surfaces to a high sheen, enhancing appearance and reducing roughness while offering some corrosion protection.

Brushed Finish

A brushed finish has fine, parallel lines for a textured look, enhancing grip and reducing fingerprints.

Sandblasting

Sandblasting uses high-pressure air and abrasive particles to clean or texture surfaces, enhancing adhesion for coatings.

Electropolish

Electropolishing is an electrochemical process that smooths and brightens metal surfaces, removing imperfections and enhancing corrosion resistance.

Tolerance for CNC Milling Services

Limits for nominal size

Metals (ISO 2768- f)

Plastics (ISO 2768- m)

0.5mm* to 3mm

±0.05mm

±0.1mm

Over 3mm to 6mm

±0.05mm

±0.1mm

Over 6mm to 30mm

±0.1mm

±0.2mm

Over 30mm to 120mm

±0.15mm

±0.3mm

Over 120mm to 400mm

±0.2mm

±0.5mm

Over 400mm to 1000mm

±0.4mm

±0.8mm

Over 1000mm to 2000mm

±0.5mm

±1.2mm

Talk to us

Online quotes

LATEST NEWS

CNC machining cost

CNC machining (Computer Numerical Control machining) is a precise tools to shape and, learn more…